Content

- Drive Bearings - ball bearings minneapolis

- The Bearing - bearings minneapolis

- Sorts Of Direct Actuators - ball bearings minnesota

- Ceramic Bearings - bearing distributor minnesota

- Chapter 3: Applications & Advantages Of Ball Bearings - ball bearings minneapolis

- Why Should You Utilize Plastic Bearings In The Food Handling As Well As Manufacturing Sector? - bearings minneapolis

Drive Bearings - ball bearings minneapolis

THE ADVANTAGES OF DEEP GROOVE SPHERE BEARINGS

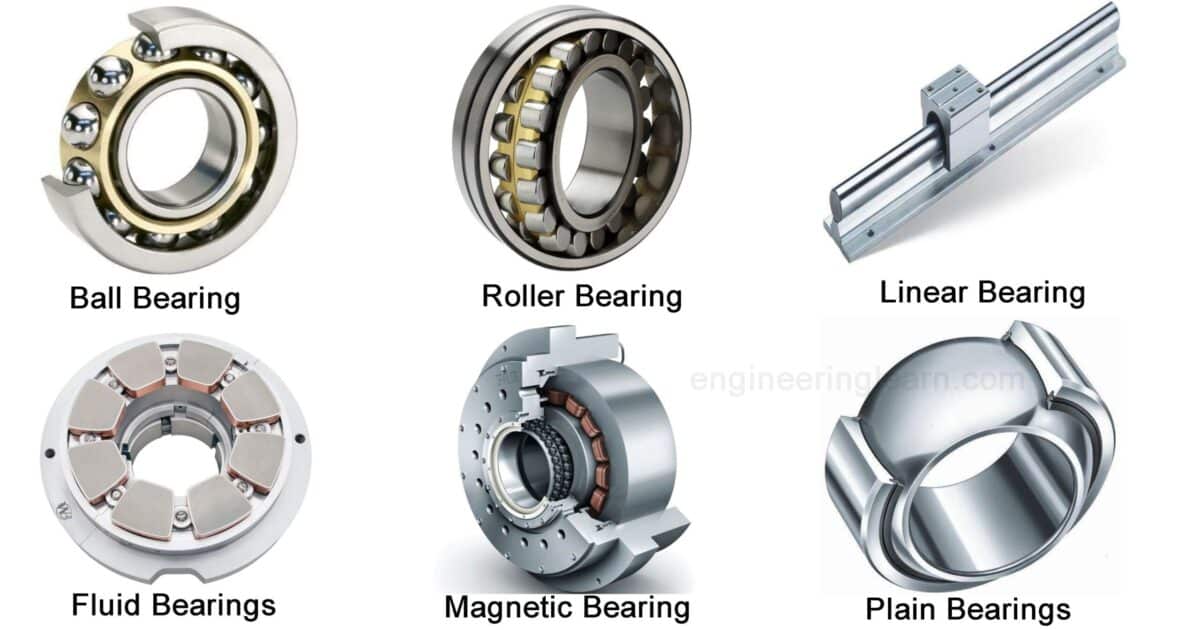

Moving bearings are an important component of turning or oscillating machine elements. They aid support and direct rotational motion and transfer tons between different elements, such as axles, shafts, and also wheels. Sphere bearings are a sort of rolling bearing that have a ball rolling component. This round beings in a ring raceway, or groove, resulting in a reasonably reduced contact area. The minimized contact area decreases rubbing however restricts the weight the bearing can carry. Round bearings are typically utilized in high-speed, low-load applications, where their lowered friction, noise, and also vibration assistance stop excess damage. Round bearings usually suit radial loads or loads that are perpendicular to the shaft. While some ball bearing kinds can take care of axial loads (alongside the shaft), they're commonly limited to very reduced carrying capabilities.

What are Deep Groove Round Bearings?

Deep groove ball bearings are similar to typical bearings yet have raceways that closely fit the measurements of the rounds that run in them. These deep grooves result in spheres that are a lot more secure and can handle greater lots than shallow-groove bearings. They still offer reduced rubbing, and the deep groove additionally limits resonance and noise while additionally supplying the ability for some axial load capability. If you have actually ever seen any kind of sort of round bearing, opportunities are you were looking at a deep groove sphere bearing. These bearings are some of one of the most common because of their flexibility, availability, and low rubbing. They're suitable for high rotational rates and provide a number of advantages over other ball bearing kinds. These bearings can be found in a large variety of layouts, dimensions, and load-bearing capacities, making them optimal for residence or commercial use. Likewise, it's straightforward to replace standard bearings with deep groove round bearings, which can improve the longevity as well as effectiveness of the maker.

Kinds Of Deep Groove Ball Bearings

Producers have fine-tuned the layout of deep groove bearings for many years, resulting in a number of different kinds. These kinds are generally far better suited to a particular application where a deep groove bearing isn't ideal. Single-Row Deep Groove Round Bearings This is the normal deep groove round birthing that has a single raceway. These are typically robust as well as made from long lasting materials, making certain that these bearings have an extended service life. Single-row deep groove ball bearings are likewise subdivided right into various other types, ranging from 3 mm to 400 mm birthed sizes, suitable for practically any type of application. Some manufacturers will certainly also supply slim, narrow, broad, or mini bearings depending upon customers' requirements.

- Koyo lately raised their bearings vibrant tons ratings by 25% because of constant renovations in making procedures and also the sanitation of steel over the previous twenty years.

- Linear Rails are perfect for moving products with a production process with fantastic precision and also as little rubbing as feasible if developing, packaging, and distributing products.

- The ball bearing should suit its application depending on the discussed parameters.

- Choosing hybrid radial or angular get in touch with bearings over traditional steel bearings uses crucial efficiency benefits.

- In several applications, one race is connected to the rotating assembly (e.g. a shaft or hub), as well as the other race is stationary.

Because deep groove ball bearings need to endure extreme problems, manufacturers likewise offer ceramic-coated bearings to handle electric matching and high-temperature devices that can hold up against approximately 660 levels F. Among the current growths in single-row deep groove sphere bearings is the sensor-bearing system, which can determine the condition of the ball bearing elements. These devices are easy and easy to use as well as can assist with speed noticing, angular position measuring, and steering, making them useful in electric motors, tractors, conveyors, as well as roadway rollers.

Kinds Of Direct Actuators - bearings minneapolis

Secured Deep Groove Sphere Bearings

Secured deep groove sphere bearings resemble single-row bearings, except that they have steel or rubber guards installed on one or both sides of the bearing. These seals are pre-lubricated with grease to prolong the lifespan of the bearing. Lots of manufacturers utilized covered round bearings in contaminated atmospheres that might otherwise affect the performance of the bearing. The guards aid the bearing keep oil while also avoiding any type of contaminants from entering the bearing itself. Larger deep groove sphere bearings might even utilize machined brass cages for high-speed applications, where the cage protects against unwanted damage.

Flanged Deep Groove Ball Bearings

Some deep groove sphere bearings feature a flanged outer ring, which functions in a similar way to a snap ring on basic sphere bearings. The flange enhances the bearing's running performance and is also simpler to maker as a result of the simplicity of the housing birthed. Flanged deep groove round bearings are excellent for birthing axial lots, such as in tube ends or on belt guide rollers. Some versions also have swivel housing to enable minor imbalances and also better axial tons.

Double-Row Deep Groove Round Bearings.

The double-row layout allows for a substantially greater lots carrying capability while still retaining the bearing's low rubbing features. Double-row bearings are generally just a little bigger than their single-row more info equivalents, making them almost as flexible as well as sensible. The major drawback of double-row deep groove sphere bearings is that they do not included seals or guards, though some may be fitted with cages. These cages help with setup and also setting up but are susceptible to mechanical tensions throughout procedure. It's essential to choose the right type of cage for the specific application, especially as some cage materials are sensitive to particular lubricating substances.